Intermountain Packing guarantees reliability with Full Gauge, Hillphoenix, and Bitzer solutions

The joint analysis from Full Gauge, Bitzer, and Hillphoenix enabled failure correction, stabilized the operation, and mitigated risks.

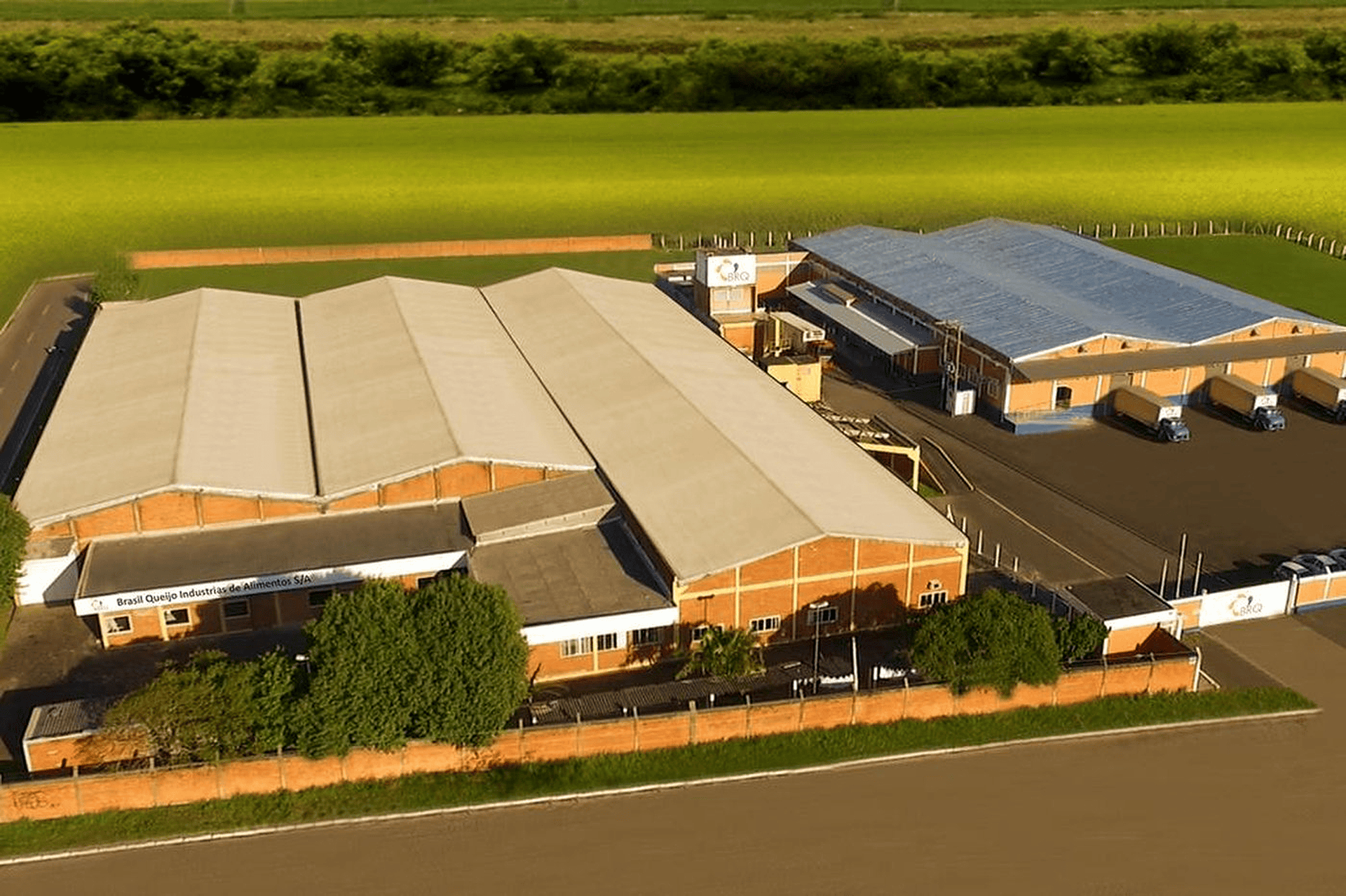

BRQfoods is one of the leading companies in the production of dairy products, supplying to all main dairy brands in Brazil. With manufacturing units in three different States, the company operates with an integrated model that includes from the milk collection to the final industrialization, moving millions of liters and tons of product every month. In this highly complex production scenario, where stages such as pasteurization, maturing, cooling, and storage demand rigorous control, it is essential to maintain stability, traceability, and operational efficiency.

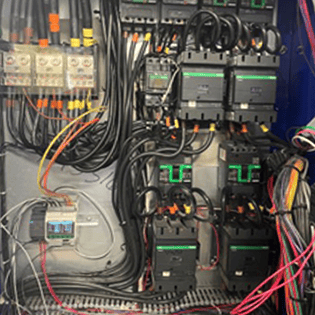

It was from this necessity that in 2024 BRQfoods started using several controller models from Full Gauge Controls, associated with the remote management system Sitrad. Before implementing, the team needed to keep constant monitoring of the control panels and record manually, a process that was time consuming and increased the risk of failures along the production line. With the adoption of Full Gauge controllers for temperature, humidity, and pressure integrated with Sitrad, the refrigeration management of the units became automated and centralized, allowing a continuous follow-up in real time, and more importantly, the ability to directly act on the software in case a parameter deviates from the standard.

According to Everton Breunig, the Operations Director of GrupoBRQ, the implementation was simple and performed by their own team, with a quick adaptation to the system. “Sitrad is intuitive. In a few weeks we were operating with complete control over the system,” he mentions.

BRQfoods now has automated alarms in case of deviations from standards and a detailed data history, facilitating analysis and assertive decision-making. Among the observed results, we can find:

• Higher food safety, with a quick identification of temperature changes, avoiding quality loss or waste;

• Optimization of equipment use, through the graphic analysis of the ammonia system behavior, allowing adjustments in the compressors’ work regime and contributing to the reduction of starts, worked hours, and maintenance costs;

• Precise control of critical processes, such as milk and cream pasteurization, guaranteeing sanitary compliance. The fluids stock monitoring such as milk, cream, and whey, is also being managed more precisely, promoting predictability and better operational planning.

When evaluating the benefits, Everton reinforces his trust in Full Gauge and Sitrad: “We recommend using Full Gauge controllers and Sitrad, due to the ease of implementation, an excellent cost-benefit ratio, and the direct contribution to cost reduction, and loss prevention, which are extremely important in the production process.”

The joint analysis from Full Gauge, Bitzer, and Hillphoenix enabled failure correction, stabilized the operation, and mitigated risks.

The Valinhos Unit, in São Paulo, Brazil, has invested in solutions such as Sitrad since 2013, increasing resources and redundancy to ensure complete traceability and stability.

The Cold Storage company that was serving only its neighborhood before, rapidly expanded its client base, and today it is recognized in the entire city.

The Biological Institute (IB) in Campinas, in Brazil, a national and international leader in animal and plant health research has modernized the unit’s […]