Campinas Biological Institute adopts Full Gauge technology for a precise climate control

The Biological Institute (IB) in Campinas, in Brazil, a national and international leader in animal and plant health research has modernized the unit’s […]

A small cold storage of 250 m², located in Campinas, Brazil, needed to achieve the municipal sanitary certification (SIM) to increase its market share. Celsus Espetinhos had a big challenge: with a small budged, it operated cold chambers equipped with controllers from competing brands, that had unstable performance and put the product conservation at risk, even causing losses.

The responsible for the Project, Mr. Cláudio Torres, from DN Refrigeração, explained that this scenario is pretty common among small entrepreneurs in the industry. “Smaller-sized clients have challenges when purchasing products due to pricing. They always prioritize pricing,” he states. The initial Budget for a complete thermal qualification was close to R$50 thousand, a non-viable amount for the industry.

To revert the situation, DN Refrigeração proposed an affordable solution: replace teh existing controllers for Full Gauge Controls TC-900E Log models, which are capable of registering real-time temperature data. For 15 days, the information gathered allowed a precise diagnostic of the chambers. Sanitary Vigilance was demanding strict standards: freezing between –26 °C and –30 °C, raw materials reception between –2 °C and +1 °C and controlled temperatures in the curing and stabilization stages. The initial analysis showed just –24 °C at nights, remaining at –18 °C during the day.

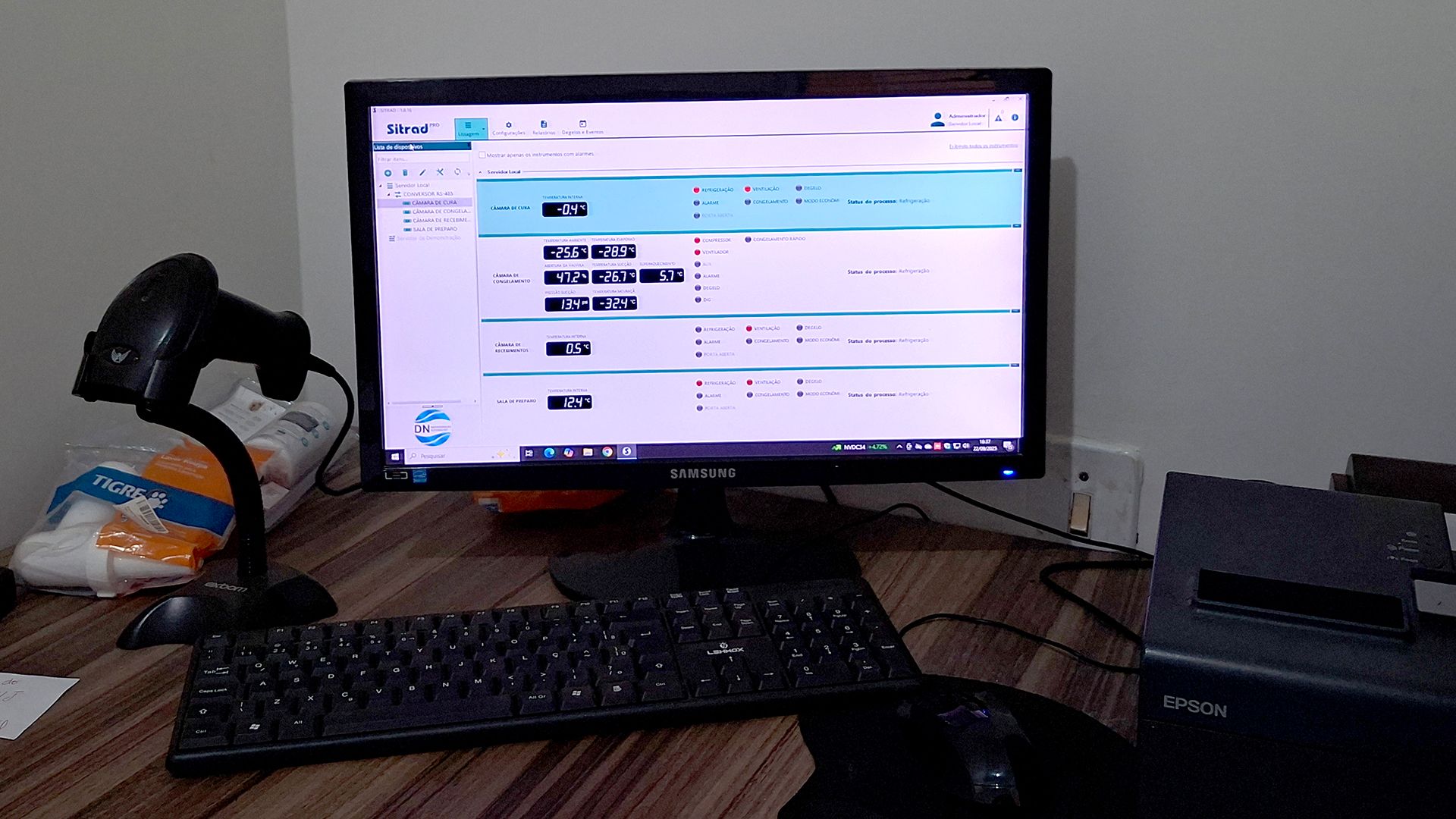

Based on this data, a dual redundancy strategy was implemented: the TC-900E Log as a main data gathering tool and the TCP-485 Wi-Fi Log as a backup, guaranteeing information integrity even in case of reset or power failures. The whole system was moved to Sitrad management, made available without any additional costs, and complying with the standards from ANVISA and FDA, which ensured easy access to history, alarms and operation parameters. “The free software offered by Full Gauge is what hooks small-sized clients,” highlights Cláudio.

To increase the production capacity and solve the temperature problem, Cláudio installed a VX-1025E electronic expansion valve from Full Gauge, parameterized to optimize the superheating initial opening and control. The adjustment reduced the current peak on the compressor in almost 50%, and generated power savings of around 30%. “With the simple and basic measures, and Full Gauge technology, I was able to help the client double its production,” celebrates the technician.

The results were immediate: the chamber maintained –24 °C during the day and –30 °C at night, with a reduction in almost six hours in the daily freezing time. The complete traceability of the data, guaranteed by Sitrad and by the controllers, enabled the company to comply with the demands of Sanitary Vigilance and guaranteed the municipal certification. The Cold Storage company that was serving only its neighborhood before, rapidly expanded its client base, and today it is recognized in the entire city, planning to reach soon the entire metropolitan region, and installing three more electronic expansion valves from Full Gauge Controls.

The Biological Institute (IB) in Campinas, in Brazil, a national and international leader in animal and plant health research has modernized the unit’s […]

Leotech Group achieves efficiency in refrigeration systems and operational peace or mind for their clients with Full Gauge Controls solutions